New product development, especially in the consumer electronics marketplace, is focused on smaller, lighter products. Virtually every new product design is coupled with a desire to produce more compact products requiring thinner wall sections in components, housings and covers. Today, the medical device, portable electronic, laptop/notebook computer industries and others, have applications where wall thicknesses are often less than one half of a millimeter.

Experience has shown that risk increases when thinner wall applications are approached independently from a design, processing or tooling point of view. Losang offers an integrated systems approach to thin wall injection molding that does not separate design, tooling or manufacturing. When the inter-relationship between these functions is clearly understood, the chances for Six Sigma quality are the greatest.

|

|

|

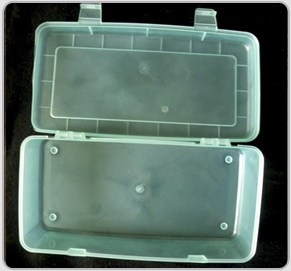

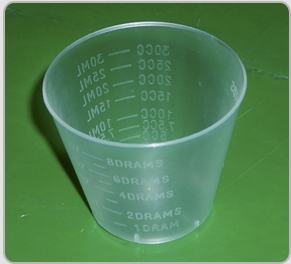

Thin Walled Plastic Components | ||

The benefits associated with thinner wall sections include:

● Reduction in overall component size and weight.

● Opportunities to reduce costs by reducing material usage and processing cycle times.

● Reduction in wall thickness is translatable to larger parts as well.

Typical thin wall applications include:

● Cellular phone components.

● Laptop/notebook computer components.

● Hand held devices.

● Medical devices.

Current thin wall technology is heavily represented by applications with wall thicknesses between 0.080 and 0.050 in. (2.0 and 1.2 mm). A majority of today′s thin wall applications fall into this category. The most challenging thin wall thickness technology applications are those with wall thicknesses below 0.050 in. (1.2 mm). Such applications require new and unique design considerations. Please feel free to Contact Us for your thin wall projects.

online service

online service 86-755-89481793

86-755-89481793 sales@losangmould.com

sales@losangmould.com