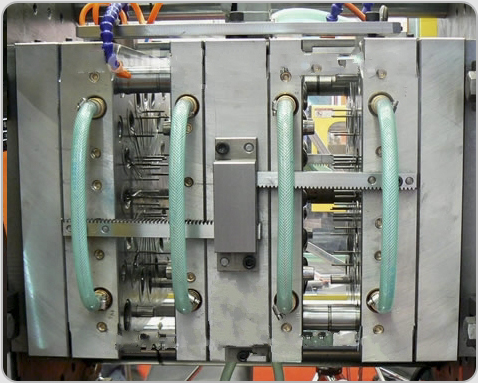

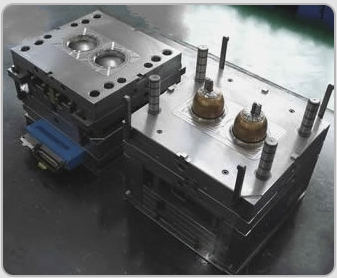

First and foremost, a stack mould is made out of two or four levels of cavities and cores assembled in one mould frame and seek to increase output via the same injection press. By increasing the output of the injection process, stack molding decreases the number of machines required to produce the same output, and thus also lowering the resources needed for upkeep and handling of the machines, and ultimately lowering costs.

Until recently, stack moulds were used for fairly small, shallow-draw packaging and other disposable items. Today, innovation has taken hold and a variety of new concepts are broadening the capabilities of stack moulds to include larger, multi-material products. Soft-touch applications such as toothbrush handles, barrier packaging, caps and closures with molded-in liners, multi-color cell phone housings, and combination-material medical parts are in high demand. As knowledge of the benefits of stack moulds increases, mould makers and customers alike look to them when applications justify their use.

|  |

Benefits of Stack Molding

● Short cycle times

● Increased output efficiency

● Fewer machines required

● Multiple part designs produced simultaneously

If you either need a manufacturer with stack mould capabilities or you′re wondering if it may be appropriate for your project. Contact Us so we can put our stack mould expertise to work for you.

online service

online service 86-755-89481793

86-755-89481793 sales@losangmould.com

sales@losangmould.com