Family Moulds is another cost-efficient solution to today's manufacturers who are seeking to improve their production productivity output without having to sacrifice quality. This is made possible by designing the injection mould so that one mould contains different parts of a product.

Another reason to use family moulds is when the production quantity is not very high in volume. This way, our customers can manufacture more than one part in one production cycle since two or more parts are produced in every shot.

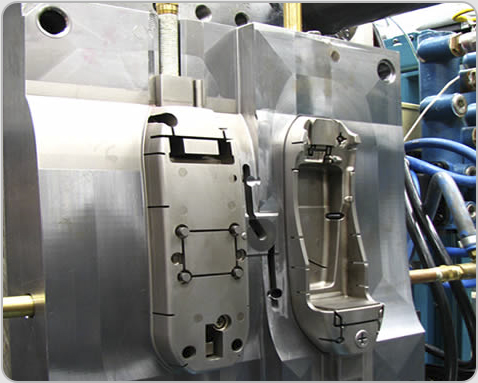

2-Cavity Family Mould for Top & Bottom Halves of Charging Cradle

Benefits of Family Molding

When the different component parts of a product are produced using the same raw plastic material, then all the more reason to use family moulds. Not only do you save on expenses in having an additional mold base, you also save on production hours! Time is saved from repetitive mould set up and multiple production cycles.

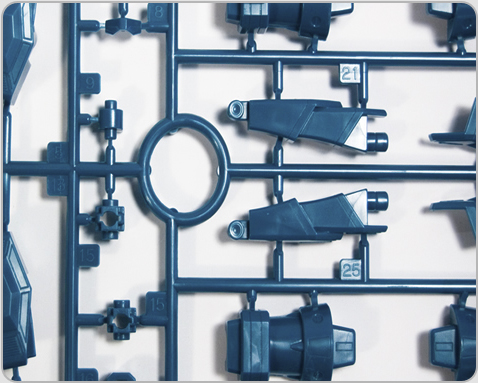

Components Created with Family Mould

Losang's plastic injection molding facilities are equipped to separate the different parts post production. Our production capacity versatility helps customers realize many benefits that not only save on monetary costs but also time and effort. Contact Us today to get a quote and learn how we can help your company save!

online service

online service 86-755-89481793

86-755-89481793 sales@losangmould.com

sales@losangmould.com