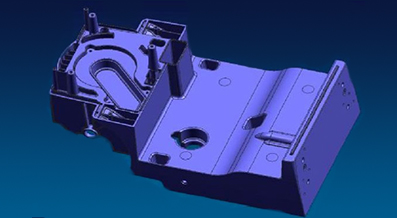

1.CAE

By using rheological and mechanical simulation software, our experienced 40 designers and engineers utilizes mold flow analysis (Polymer Flow Analysis, Mouldflow, Mould Filling Analysis & Mold Filling Simulations) to simulate flow, analyze gate location, optimize cooling and validate part and tool design before industrilization.

|

|

|

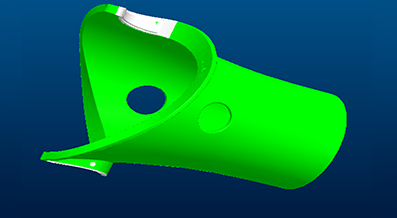

2.Product Development

By using rheological and mechanical simulation software, our experienced 40 designers and engineers utilizes mold flow analysis (Polymer Flow Analysis, Mouldflow, Mould Filling Analysis & Mold Filling Simulations) to simulate flow, analyze gate location, optimize cooling and validate part and tool design before industrilization.

|

|

|

|

|

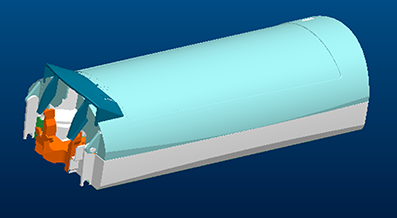

3.Mock-Up

Being used in the first step on projects, Imagery and mock-up manufacture have a goal: the idea becomes physical. We are able to provide you with virtual, full-scale model within hours. With mock-up, you will be able to analyze esthetic or functional requirements of any part before validating product design, thus being able to continue the process with maximum security. Losang has all the possibilities to realize all types of physical or virtual prototypes to scale 1:1. This is a real cost saving configuration.

|

|

|

|

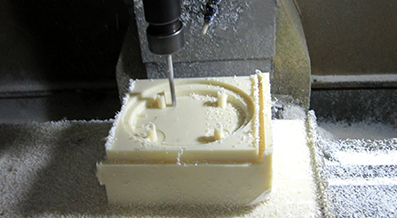

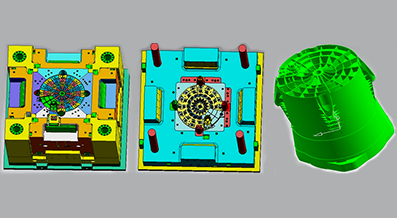

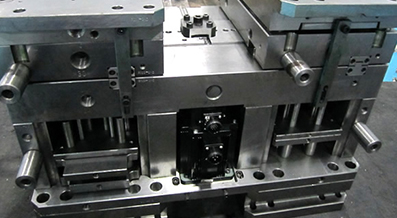

4.Prototype Mould

Our own manufacturing facilities are equipped with the newest system and technology available on the market, which sets us apart from our competitors is the quality of execution and short delivery times. Alternate materials and process, such as polyurethane injection and alloy moulds allows us to cut prototype moulds delivery times in half, while at the same time allowing you to have a pre-series made and designed just like the finished product.

|

|

|

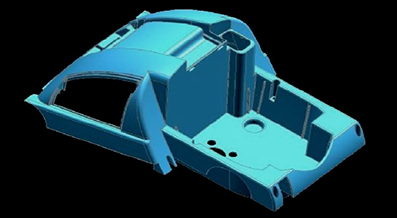

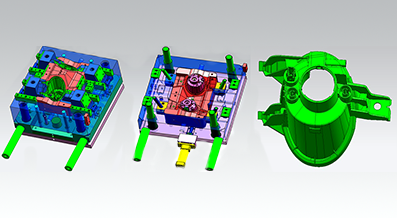

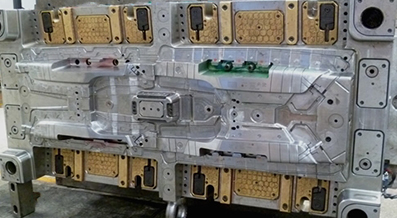

5.Mould Engineering

Losang's cross functional project management team focus on each project from design and development through design approval and production. Our know-how 3 dimensional mould design allows us to assure perfect results, no matter how complex they are. More than thousands moulds designed give us the experience required to provide you with proven solutions.

|

|

|

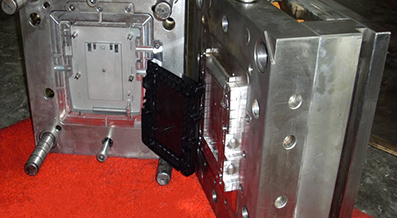

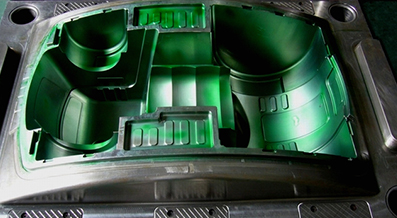

6.Mould Production

Quality. Accuracy. Speed. That's what you need from a tool shop to keep your tooling project on schedule. Losang has a more than 100-staffs tool shop that has all the horsepower and equipments to get the mould job done fast and with amazing accuracy by combine three-dimensional design with a planned machining strategy.

|

|

|

|

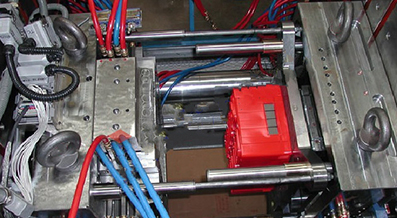

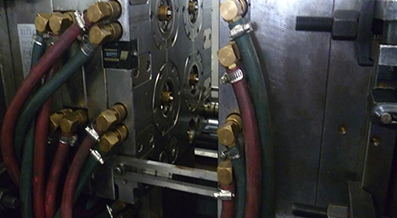

7.Mould Testing

Production ends with mould testing. Benefit from our precise moulds, world-class machine, automatic robot operation system and molding technologies. Losang is capable of sampling molds, run capability studies, produce short-run prototype parts in our in-house specialized mould testing center.

|

|

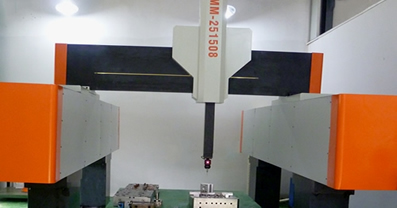

8.Metrology

By equipping with the most advanced technology, we perform all dimensional controls needed in order to guarantee compliance with specified requirements, satisfying the needs of the different internal processes, all of them are designed and controlled by our Quality Control Management System.

|

|

online service

online service 86-755-89481793

86-755-89481793 sales@losangmould.com

sales@losangmould.com