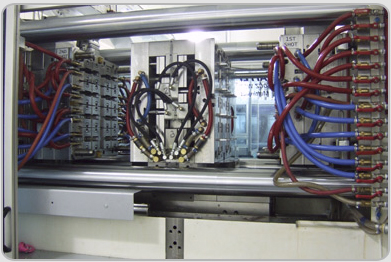

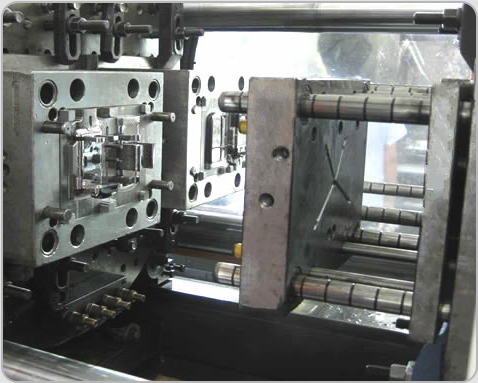

The process of 2-Shot Molding utilizes the injection of different materials into different locations on the same mold. Breaking the barrier of both form and function, multi-shot molding has come a long way since its early days of molding two or more grades of colors or resins. Today, this capability not only provides a process with long-lasting durability, but high aesthetic appeal.

Interestingly, in multi-shot molding, the mold may be moved, rotated or changed in some other way between the multi-shot injections to the moulds.

Get the level of detail, multiple color selection and use the materials you prefer, while reducing production time and complexity with multi-shot molding. Allowing you a wide range of design possibilities and providing faster processing times, two shot molding (multi-shot molding) is the process of choice for today's competitive environment.

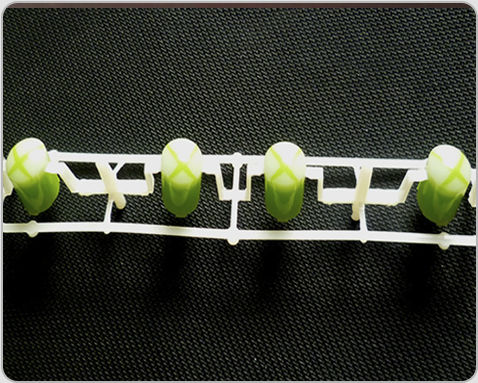

| Multi-shot Molding Advantages ● Ability to eliminate assemblies ● Durability ● Option to mold multiple materials and colors ● Tackiness – no slip ● Damping shock absorption ● Sealing ● Graphics ● No bond ● Part reduction |

|

|

|

|

|

Components Created with Two-Shot Molding | |||

Multi-Shot Molding Professionals

Our seasoned professionals are ready to solve your next multi-shot molding challenge. Contact Us right now to find out how you can save time, money and add flexibility to your injection molding project.

online service

online service 86-755-89481793

86-755-89481793 sales@losangmould.com

sales@losangmould.com