Molded in separate operations, plastic over-molding chemically bonds the different resins. By combining plastic with another material such as rubber, plastic overmolding produces a completed part with multiple material components. The overmolding material can form an insert to the plastic part or can provide cushioning, grip or other decorative or functional attributes.

Plastic Overmolding Advantages

Numerous advantages are enjoyed when using plastic overmolding. Because the plastic overmolding process allows the introduction of adhesive (where required), it eliminates a bonding step in the manufacturing process, reducing cost and time to project completion.

|

|

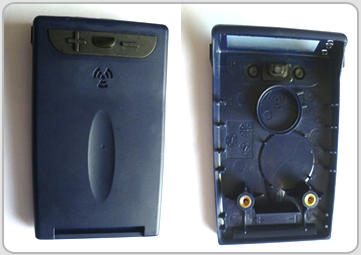

Industrial Components Created with Over-Molding | |

Plastic overmolding also allows for more combinations of materials for your finished part, as these materials are bonded together during the plastic overmolding process.

Do you need to mold complex geometric shapes, shapes with a combination of thick and thin sections, or components with undercuts? Plastic overmolding is the solution! The advanced process of plastic overmolding allows these previously unattainable goals to be reached rapidly, with high tolerances and quality levels.

|

|

|

Plastic Over-Molding Components | ||

Plastic Overmolding Professionals

Our experiences plastic overmolding professionals are ready to accept your challenge. Contact Us right now to learn about more benefits of working with us for your plastic overmolding needs.

online service

online service 86-755-89481793

86-755-89481793 sales@losangmould.com

sales@losangmould.com