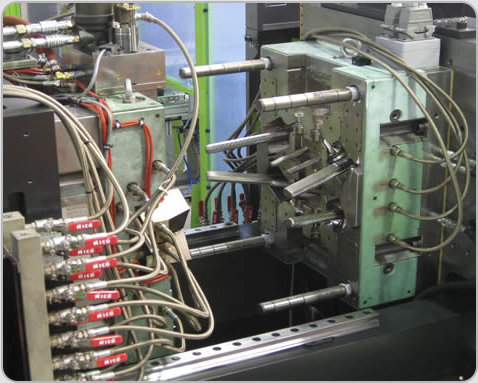

Losang has designed and built (also repaired) plastic injection moulds that use hot runner system for years. Our skill in manufacturing hot runner moulds has been very important to our customers.

Hot Runner is usually used for production with high volume, and also with multi-cavity moulds. This is so because many benefits are realized when using hot runner moulds. Listed below are just some of them:

● Lower injection & clamping pressure

● Faster Cycle & Cooling time

● Lower energy consumption

● Better located injection gates

● Cleaner injection process

● Increased output

● Possibility of contamination is lessened with no runners

● Possibility of producing the parts using smaller injection machines

● Problems on nozzle freeze or sprue sticking are eliminated

● Reduced production costs, but increased the overall profitability

● Shortened production steps

● Better plastic parts quality

● Regrinding is eliminated

● Lower resin costs

● Runner scrap eliminated or reduced

● Runner weight reduces shot size

Please free to Contact us when you are ready to use a hot runner mould. Based on experience, our customers would sometimes require a specific brand of hot runner system. We are flexible in this regard and can accommodate the brand of hot runner that will be specified by our customer. Some brands of hot runners that we are familiar with include

● Yudo

● Synventive

● Mold Master

● Husky

● DME

online service

online service 86-755-89481793

86-755-89481793 sales@losangmould.com

sales@losangmould.com